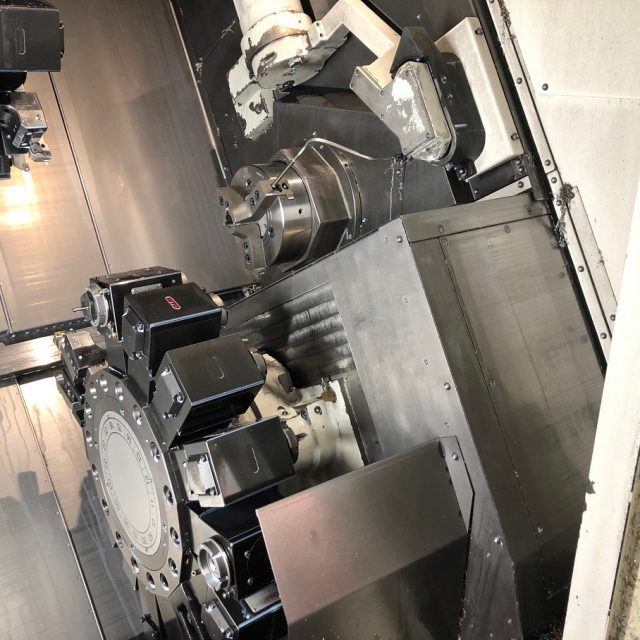

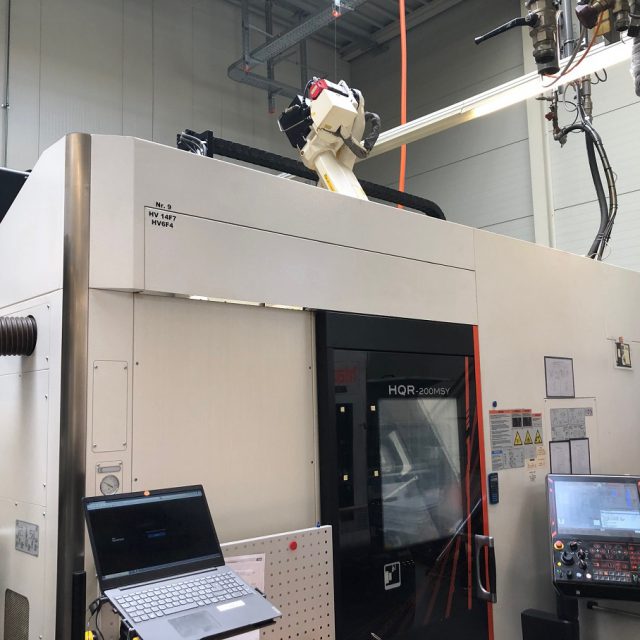

MAZAK HQR-200 MSY (U1300)SOLD

SOLD

- Reference Number

- 22022

- Year of Manufacture

- 12-2016

- Control

- Smooth G

- movements

- X1/X2-axis: 207 /141 mm

Y1/Y2-axis: 100/70 mm

Z1/Z2-axis: 1.225/1.280 mm

- Max. turning diameter (upper turret)

- 344 mm

- Max. turning diameter (lower turret)

- 210 mm

- Max. swing diameter (upper turret)

- 370 mm

- Max. swing diameter (lower turret)

- 320 mm

- main spindle

- motor output: 22/15 kW

max. spindle speed 5.000 rpm

C-axis, 0.0001°

spindle nose: A2-6

max. Stangendurchlass 65 mm - sub spindle

- motor output: 22/15 kW

max. spindle speed 5.000 rpm

C-axis, 0.0001°

spindle nose: A2-6 - tool turret

- 2 x 16-station turret

2 x 16 driven tool stations

milling drive max. speed 6.000 rpm - coolant system

- ARO filer system Typ EBF-102

– 2 off. 70 bar pumps

– 300 Liter Tank

– cooler Typ CSO 500 GC

– cooling power 5,0 kW - swarf conveyor

- rear side

- barfeeder

- - Top Automazioni XFiles-S365

- Max. bar length: 3.200 mm

- max. diameter: Ø10-65 mm

- Automatic open/close chuck

– Feedback chuck state

- Barfeeder determination function - Handling system RL100 (special construction - right side)

- Special conversion of RL100

– For parts max. Ø200 mm, Length 100mm, weight 10 kg

– Special programm sequence for bigger workpieces:

Turning operation 1, special operation for collet 1

turning operation 2, special operation for collet 2

Special programm sequence:

Barfeeder main spindle->transfer sub spindle->unloading sub spindle with RL100->storage pallet conveyor

- Special programm sequence for HD2 - other options

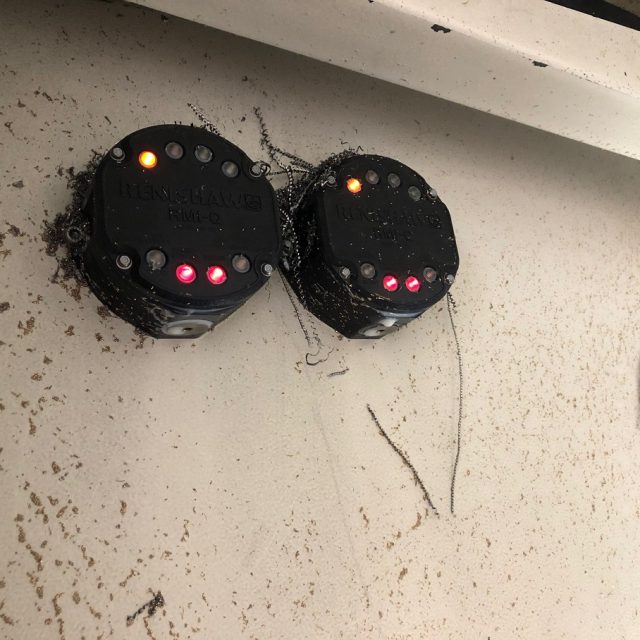

- - Renishaw probe kit RLP40

- Air blowing device at turret

- Air blowing device transfer main and sub spindle

- Safety switch

- Overload detection

- Signal lamp

- Automatic front door

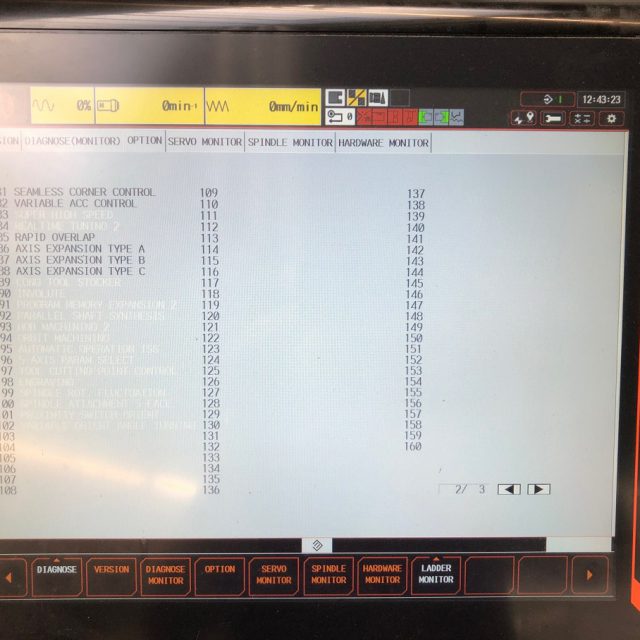

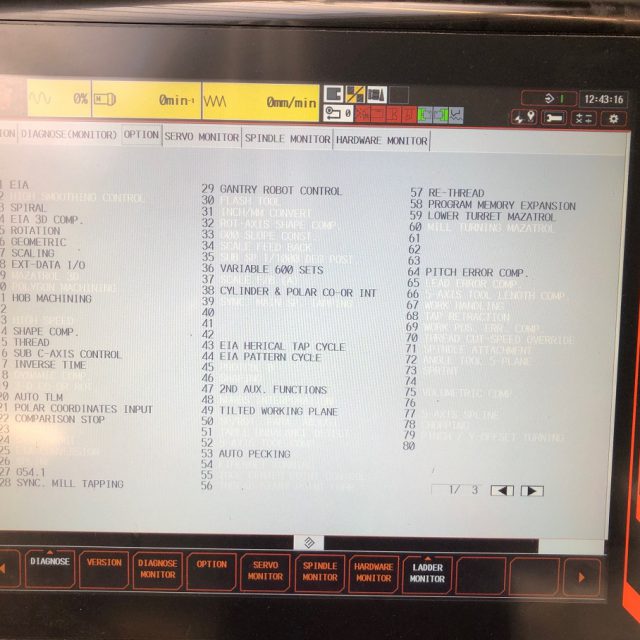

- gear hobbing function

- Max. program memory 8 MB

- Tool-offset and program memory activation

- additional M-Codes (1 Set = 2 M-Codes)

- Re-Thread function

- cylinder (G07.1) + polar interpolation (G12.1) - equipment

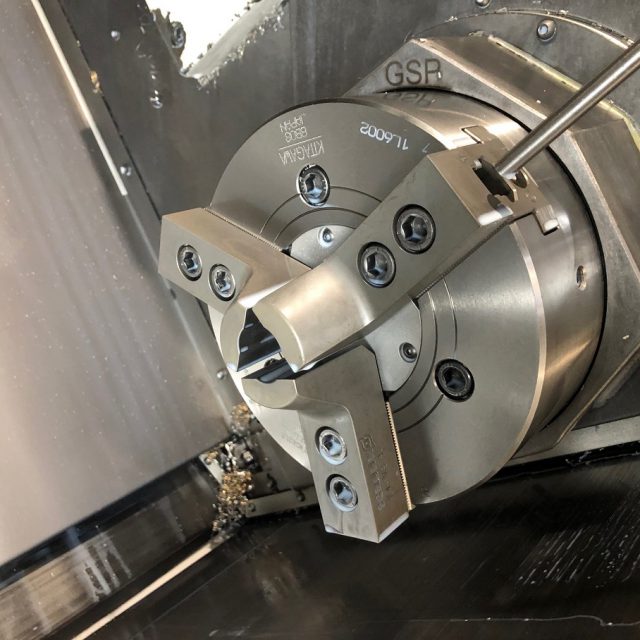

- - 2 off. 3-jawchucks Kitagawa BB-08

- 2 off. collet chucks Hainbuch TOPlus Gr 65

- Big toolholder package incl. 30 driven toolholders