DMG MORI CTX beta 1250 TC 2ndSOLD

SOLD

- Reference Number

- 23066

- Year of Manufacture

- 2017

- control

- Celos with Siemens 840D sl Operate

- max. turning diameter

- 500 mm

- max. turning length

- 1.200 mm

- Main spindle

- -ISM102

-power output: 37/28 kW

-torque: 700/600 Nm

-max. speed: 4.000 rpm - sub spindle

- -ISM76

-power output: 32/25 kW

-max. speed: 5.000 rpm

-partial hollow clamping - inner dia. of drawtube 67mm - milling spindle

- motor output: 22/19 kW

max. spindle speed 12.000 rpm

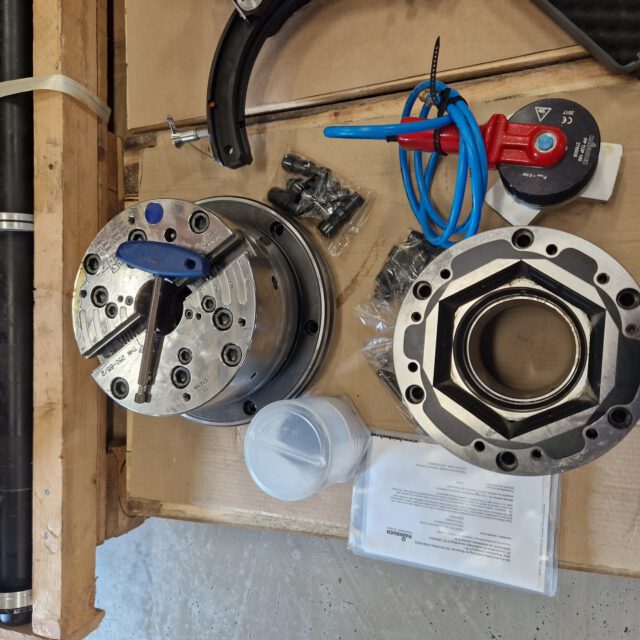

Capto C6 - Barfeeder package ø104 mm

- -parts catcher incl. conveyor for parts up to ø102 x 200 mm

-hollow clamping cylinder – inner dia. of drawtube 104 mm

-barfeeder interface

-Signal lamp, 4-fold - tool magazine / ATC

- 80 tools

- coolant system - swarf management

- - High accuracy option C-axis on main and sub spindle

- Hydraulic steady rest, SMW Autoblok K4

clamping range: 30-245 mm

- Preparation for Multitool

- Renishaw System,

RMP60 probe

- Renishaw TRS2

Tool Breakage detection

- swarf conveyor Mayfran MT10

- 20 bar high pressure pump

- API Library 2

- One-Touch IGF Advance M-D Kit

- Helical turning function

- Z-axis automatic zero point offset by touch sensor

- C-axis automatic zero offset by touch sensor

- Air blow over spindle cleaning

- CAS anti-collision control

- Structure thermal drift control (TAS-C) and spindle line (TAS-S)

- Simultaneous 5-axis kit

Super-Nurbs

Tool center point control II

Inverse time feed

DNC-DT

Tool posture command

Herical cutting

slope machining

- Gear machining package

Skyving

Hobbing - other options

- -Intertface for 6-axis robot

-interface for 6-axis robot

-Dircet scales in X-,Y- und Z-axis

-Renishaw workpiece measuring

-Renishaw NC4 tool laser, Renishaw RP1 for turning tools

-5-axis simultaneous

-Multi-Thread Cycle

-Technologie cycle alternating speed

-Tool Monitor system Artis

-MPC -Machine protection control

-Chuck rinsing device for main and sub spindle

-Clamping with balanced pressure for main and sub spindle

-Barfeeder interface – extended Profibus-Interface

-Coolant th. sub spindle

-Package for increased ambient temperature